Project Detail

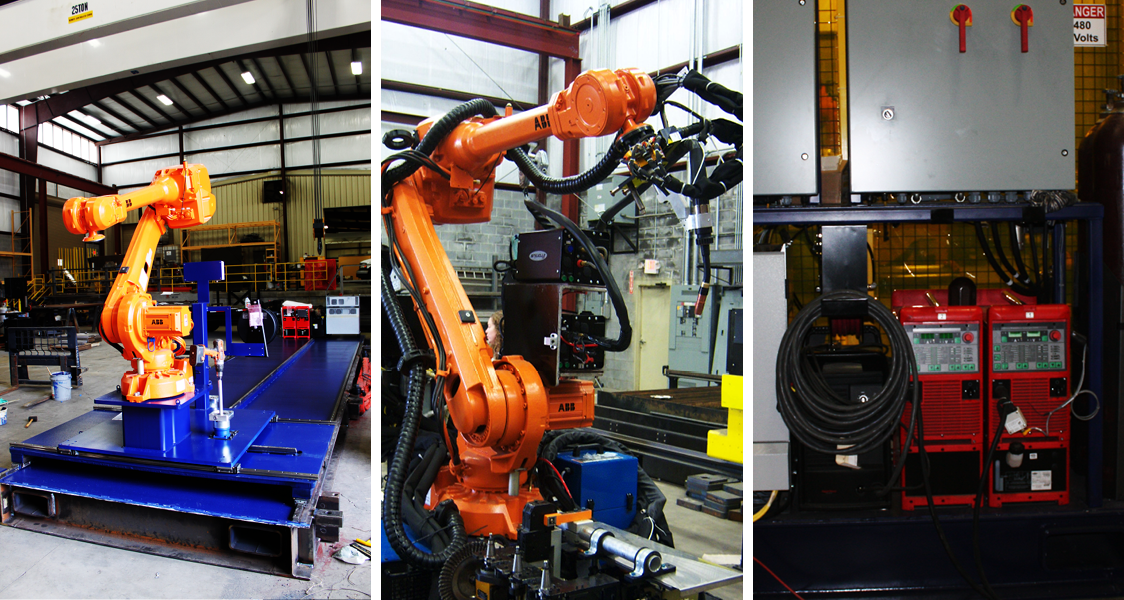

This portable robotic work cell is designed to be used for multiple welds in multiple positions. Equipped with a twin wire welding system for heavy-deposition welding, the robot can also change tools for single-torch welding, grinding, deburring, and cleaning. The robot, wire drums, tool changer, and peripheral equipment are located on a movable platform connected to a rail system. This allows movement in both directions along the X and Y axes, increasing the robot’s reach.

The Aim

Traditional engineering protocol is to bring parts to the welding cell, but these assemblies are so large the challenge is to bring the welding cells to a part, and then functionally move the cell to the next part.

The Outcome

Successful. The robot provides a level of precision, repeatability, and speed that cannot be achieved by manual processes alone. The cell has since been used for additional weldments.