Aerospace Automation Solutions

Navus automates precise, repetitive tasks for aerospace manufacturing and maintenance. Speak with our team to get started.

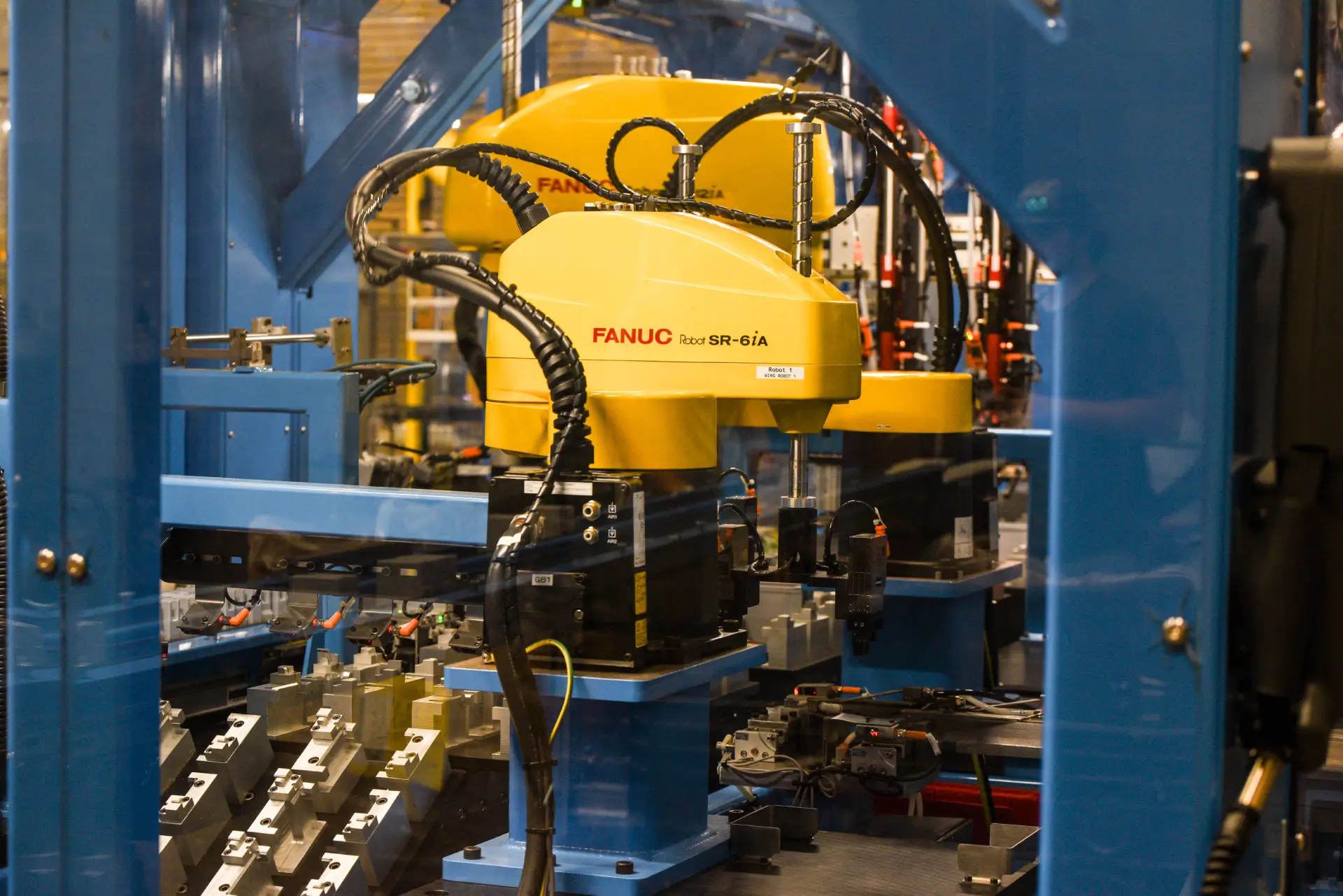

Flexible Automation for Aerospace Manufacturing

Automation is at the heart of modern aerospace manufacturing, from the precision component assembly to the even application of adhesives and sealants. Navus is a national leader in custom industrial automation, solving robotics challenges in defense, transportation, and heavy industry. Our fully integrated process handles everything from design to proof-of-concept testing in-house at our 23,000 sq. ft. facility.

Navus designs robotic cells and integrated manufacturing solutions for complicated systems when off-the-shelf machines can’t get the job done. Our expert aerospace team partners closely with you from initial strategy and design to full-scale demonstration, so you can validate new automated processes before making a full investment.

Step 1

Strategize

Our experts will consult with your team to develop a strategic, data-driven automation plan, based on a comprehensive analysis of your current production operations, pain points, and business goals.

Step 2

Build

We enter the design and engineering phase to develop a reliable, replicable, custom solution tailored to your exact specifications and performance requirements.

Step 3

Implement

When everything’s ready, we handle installation and integration into your existing facility, as well as comprehensive training for your team and ongoing support for peak performance.

Custom Automation for the Aerospace Industry

Aerospace automation prioritizes output quality and human safety. Navus develops advanced robotic welding cells that can perform tasks including preparation, welding, and post-inspection remotely, reducing human exposure to harsh environments. Our automations lead to faster throughput and optimized material usage, saving time and money.

While the market is full of robotic welding solutions, not every machine is built for aerospace. Navus works with manufacturers who must adhere to stringent safety standards and precise heat control, often requiring the welding of intricate pieces in hazardous environments. Our engineers develop custom designs suited to your use case and thoroughly validate each concept before moving into full-scale production.

On installation day, we provide on-site training for your team to ensure your automation system operates at peak efficiency, and we have ongoing parts and service support for the full maintenance lifecycle of your equipment. Get in touch with our aerospace automation team to review the details of your next project.

Consumer Products Automation Projects

Our Results

“Navus provided a custom cell utilizing six robots to weld and clean oddly-shaped parts weighing up to 30 tons that reduced the part manufacturing time by 53%.”

Consult with Our Experts

Schedule a no-obligation call to discuss your project with the Navus team. Let’s forge a better future together.