Forging Automation Solutions

Navus develops and builds robotic solutions for heavy lifting and material transfer in the forging industry. Consult with our automation experts to get started.

Robotic Automation Solutions for Foundries

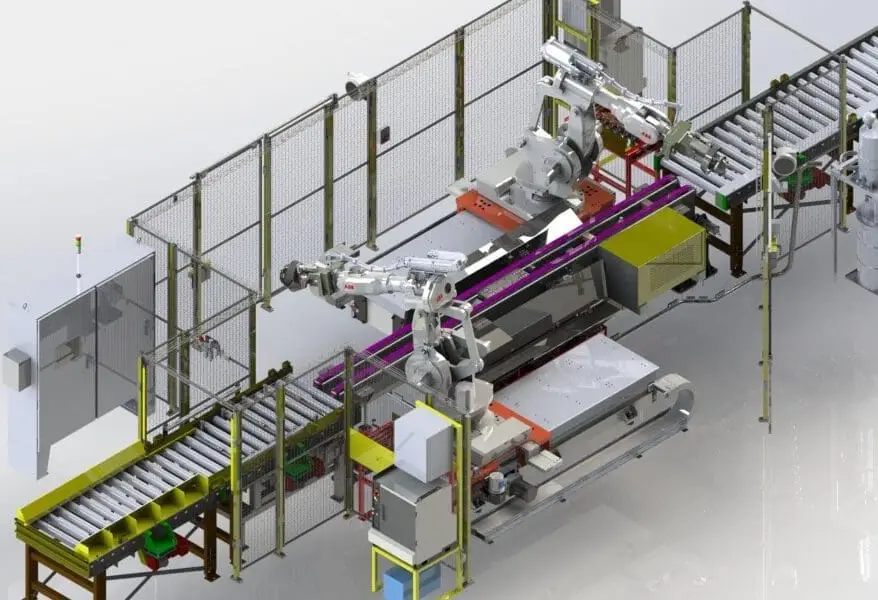

Forging automation prioritizes safety, simplicity, and precision to create consistent, high-quality outputs. Navus specializes in designing and building custom robotic solutions for hazardous tasks, including welding, heavy lifting, and hot material handling. We help forging manufacturers increase throughput with turnkey solutions crafted for specific environments.

When you partner with Navus, you’ll receive end-to-end support from design to installation. We conduct extensive in-house testing and simulations to validate concepts and verify cycle times. On installation day, we provide extensive on-site training for your team and ongoing technical support. Contact us today to see how you can achieve faster production, better quality, and a safer forging environment.

Step 1

Strategize

Our experts will consult with your team to develop a strategic, data-driven automation plan, based on a comprehensive analysis of your current production operations, pain points, and business goals.

Step 2

Build

We enter the design and engineering phase to develop a reliable, replicable, custom solution tailored to your exact specifications and performance requirements.

Step 3

Implement

When everything’s ready, we handle installation and integration into your existing facility, as well as comprehensive training for your team and ongoing support for peak performance.

Custom Automation for Forging and Foundries

Robotic automation is the new standard for forged parts manufacturers. As the forging industry grapples with labor shortages and increased market competition, top producers rely on robotic solutions to increase speed while maintaining high degrees of precision and quality control. When you can’t afford to fall behind, Navus is your trusted automation partner.

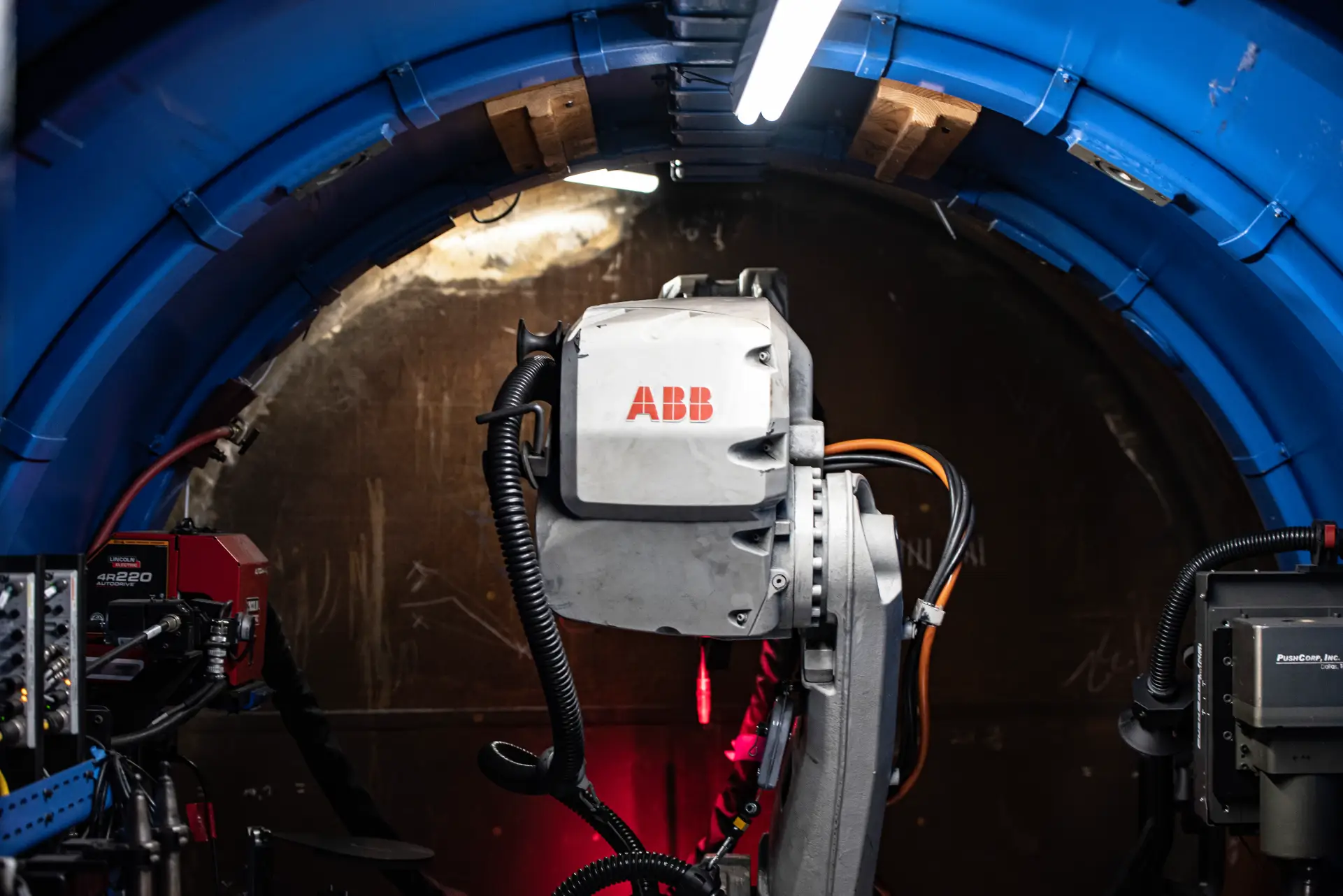

For more than 25 years, our expert engineers have crafted customized solutions for heavy industry and robotic welding projects. Whether you need sensor-guided precision or highly specialized end-of-arm tooling, we assess your foundry environment and production process to design integrated solutions that achieve faster production times and safer factory floors.

We understand the unique challenges of the forging industry, and we approach every project with risk reduction and consistent output in mind. All concepts are thoroughly simulated and tested prior to scaling production, and we use industry-leading heat-resistant materials designed for harsh foundry conditions. Connect with our team today for an introductory consultation.

Consumer Products Automation Projects

Our Results

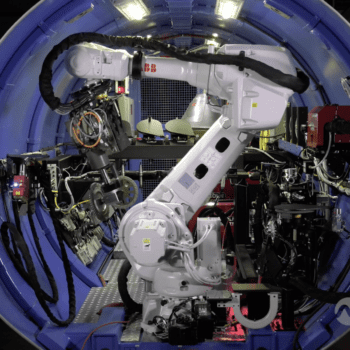

“This project required extensive engineering and design to develop a welding cell with an unprecedented feature-set that produces welds capable of withstanding the rigors of ultrasonic testing.”

Consult with Our Experts

Schedule a no-obligation call to discuss your project with the Navus team. Let’s forge a better future together.