Shipyard Welding Automation

Navus develops fully integrated welding and material handling systems for the shipbuilding industry, custom-designed and validated in-house.

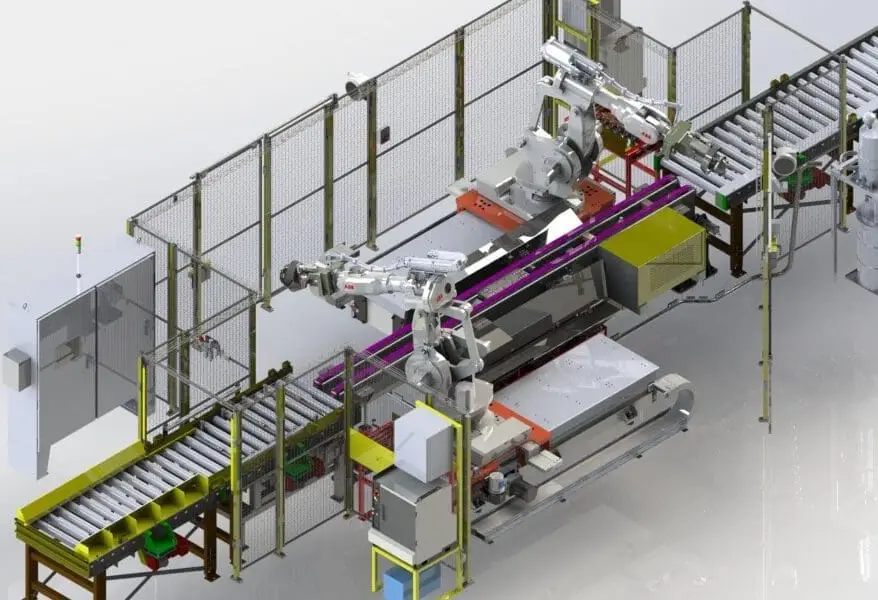

Large-Scale Robotics for the Maritime Industry

Modern shipbuilding requires advanced robotic welding mechanisms and customized systems for heavy material handling and assembly. Navus thrives in designing custom weld cells for large, oddly-shaped parts. Our heavy-industry facility, including a 25-ton gantry crane, allows us to test and validate systems in-house.

Shipyards need guided systems capable of complex task-switching and high degrees of precision. When you work with Navus, we begin with a comprehensive analysis of your current operations and a simulation proof of concept to ensure our final deployment accelerates your production right out of the gate. No task is too big for our team to tackle.

Step 1

Strategize

Our experts will consult with your team to develop a strategic, data-driven automation plan, based on a comprehensive analysis of your current production operations, pain points, and business goals.

Step 2

Build

We enter the design and engineering phase to develop a reliable, replicable, custom solution tailored to your exact specifications and performance requirements.

Step 3

Implement

When everything’s ready, we handle installation and integration into your existing facility, as well as comprehensive training for your team and ongoing support for peak performance.

Custom Automation for Shipbuilding

Shipbuilding has changed dramatically in the past decade as welding assembly tasks have been increasingly automated. We’ve seen an increase in lightweight and composite materials, as well as a push toward modular design. When you need an automation partner to keep up with the rapidly changing industry, Navus is your team.

Our 23,000 sq. ft. facility features a 25-foot bay door and is fully equipped for heavy industry concepting and assembly. We’re vertically integrated and go from initial CAD drawings to final proof of concept in house. When we’re ready to install, we provide on-site training and ongoing support for your team.

No matter your challenge, from sensor-guided toolpath execution to high-performance tactical welding systems, Navus delivers custom-developed turnkey solutions. We’ve worked with defense contractors and commercial shipping companies to deliver world-class automation systems. Get in touch today for a consultation with our experts.

Shipyard Welding Automation Projects

Our Results

“The system that Navus designed took a process that traditionally took 16 hours and accomplished it in 4 hours.”

Consult with Our Experts

Schedule a no-obligation call to discuss your project with the Navus team. Let’s forge a better future together.