Our Capabilities

Custom Robotic Welding

With years of research and development and a certified weld inspector on staff, Navus has developed strategies for tackling the toughest welding problems, including out-of-position welding and laser seam tracking for complex joint configurations. We’ve developed solutions for Fortune 500 companies in transportation, military, automation, consumer goods, and more.

Rigorous In-House Testing

Our robotic welding solutions stand up to the most rigorous testing procedures, including X-Ray, UT, and TOFD. We can also develop custom profiles for consistent tracking and adaptive control. Navus has the experience and in-house testing capabilities to perfect your processes with efficient, reliable automated welding systems.

Remote Operation and Monitoring

Welding can provide extremely harsh work environments. Navus proudly offers remote operating solutions to keep your workers safe. Our capabilities include live weld puddle monitoring, high definition pre- and post-welding inspections, and numerous weld analysis features.

Projects Gallery

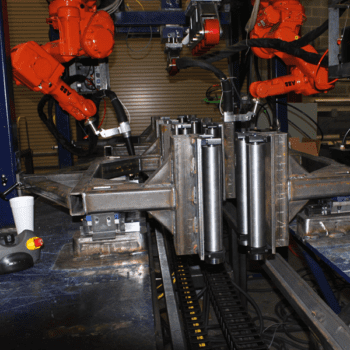

T-Beam Welder

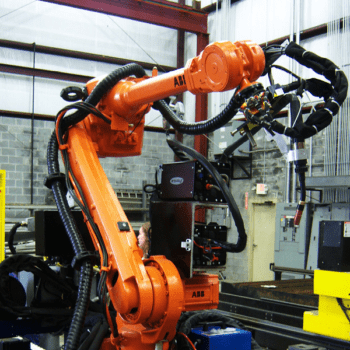

Portable Weld Cell

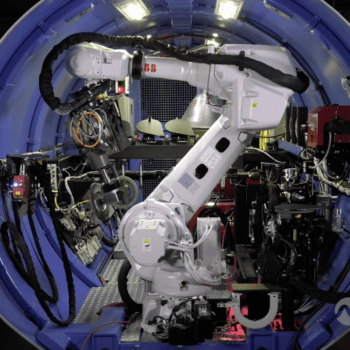

Tactical Welding System

The Advantages of Robotic Welding Technology

Navus isn’t the only company that can sell you a robotic welder. But too many vendors push off-the-shelf solutions without conducting an analysis on the long-term ROI or considering the best opportunities for efficiency in your current production systems.

With Navus, you get a full-service, concept-to-completion, comprehensive approach to robotic welding. We dive deep into your existing technology and specific needs so we can recommend solutions guaranteed to cut your production time and streamline your workflow.

Our customized solutions provide complete flexibility for your specific use cases, ensuring you get the maximum benefit from your investment. We provide full on-site training and post-installation support to make sure your advanced robotic welding system is programmed correctly and highly efficient.

With more than 25 years of development and a certified weld inspector on staff, Navus has innovated solutions for laser seam tracking and remote operation for many Fortune 500 companies in heavy equipment and consumer manufacturing.

If you can’t afford downtime and unexpected maintenance issues, call us. Our world-class team will take your project from start to finish to ensure we’re solving your most pressing issues.

The Navus Difference

What People Are Saying

“My favorite part of the job is solving challenges for our clients.

New technology comes out every year, and we’re constantly working together to tackle problems in creative ways.”

Aaron Murr, Shop Lead

Consult with Our Experts

Schedule a no-obligation call to discuss your project with the Navus team. Let’s forge a better future together.