Our Capabilities

Wire Arc DED Additive Manufacturing

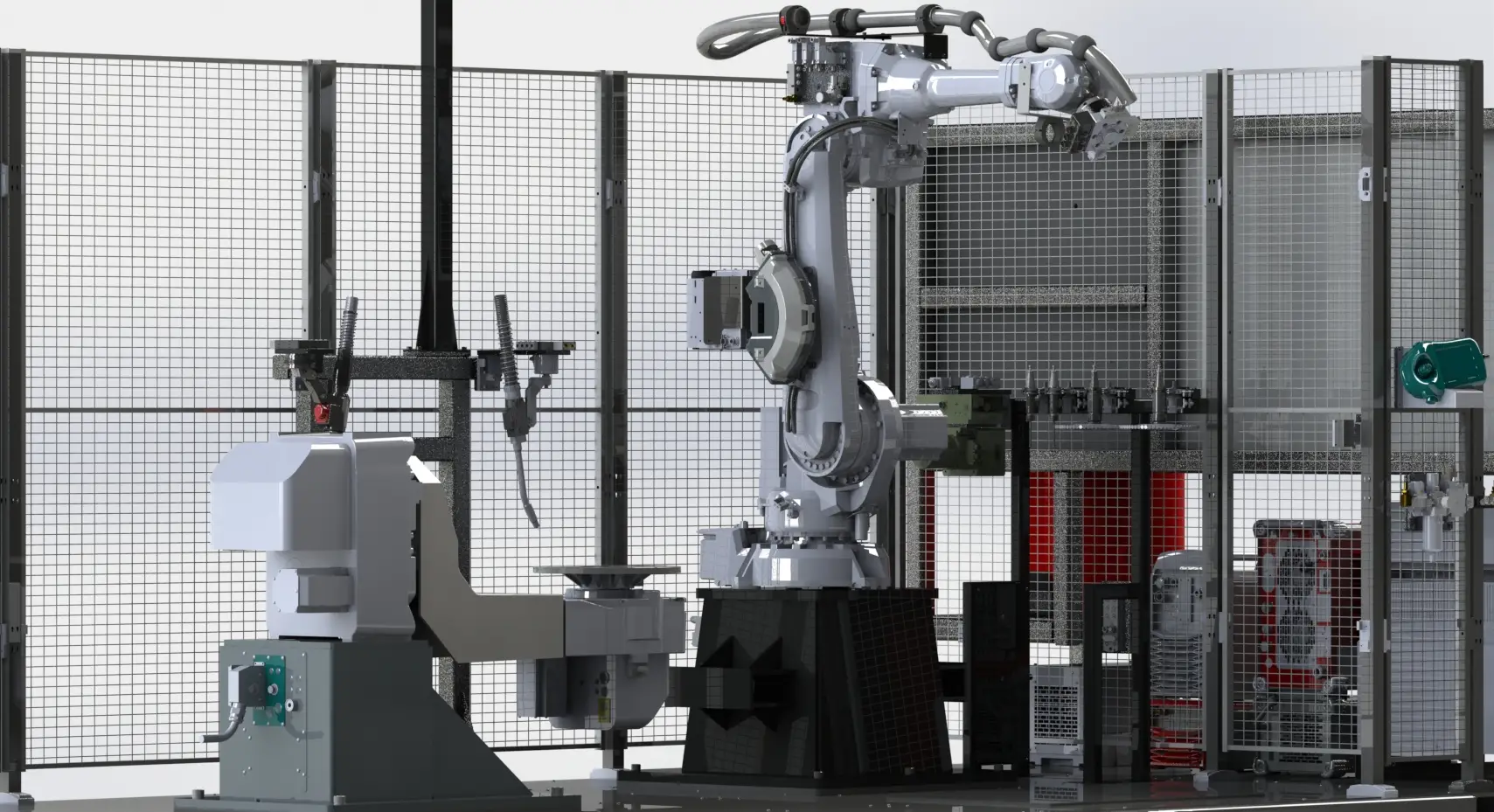

Navus creates customizable systems for on-demand printing of low-volume, large-scale metal components. Using industry-leading wire arc additive manufacturing technology, we work with DOD/DOW and DOE suppliers to supply cost-effective printing systems for the building or repair of complex metal parts.

Parameter Flexibility

Navus helps you define profiles for multiple parts and manage parameter controls when switching materials. Our systems handle a wide range of part sizes, including components of 4,000+ lbs. We have the flexibility to deposit multiple metal materials, including ultra-high strength steels and corrosion-resistant inconel and nickel-based alloys.

Supporting Process Technologies

Our modular, multi-process tools integrate materials into a single connected system for streamlined production and near net shape manufacturing. Our real-time, in-situ monitoring ensures process stability and prevents materials waste. Talk with DED additive manufacturing experts for a comprehensive consultation on your project.

What Is Additive Manufacturing?

Wire arc directed energy deposition, also called wire arc additive manufacturing (WAAM), is a 3D printing process that layers metal deposits for the building or repair of highly complex parts. WAAM uses a welding robot for the high-precision melting of metal wire to significantly reduce lead times on new manufacturing and to make rapid repairs of large components.

Navus works with DOD/DOW and DOE suppliers to design customizable systems for heavy, low-volume, high-mix parts. From shipbuilding applications including propellers and rudders, to connector housings and piping components for the energy industry, our systems can be scaled for 4,000+ lb components requiring multiple metal deposits.

We handle all stages of the build process under one roof, from design to testing to delivery, giving you assurance that the end result will increase efficiency and drastically reduce material waste. Trust Navus for an expert, economical approach to your manufacturing challenges. Consult with our team today for a customized approach.

The Navus Difference

What People Are Saying

“My favorite part of the job is solving challenges for our clients.

New technology comes out every year, and we’re constantly working together to tackle problems in creative ways.”

Aaron Murr, Shop Lead

Consult with Our Experts

Schedule a no-obligation call to discuss your project with the Navus team. Let’s forge a better future together.